Semi-Truck Filter Maintenance Services

At DPF Solutions, we specialize in cleaning diesel particulate filters (DPF) for semi-trucks. Our dedicated team offers a comprehensive range of services designed to keep your trucks running efficiently and sustainably. We serve truck owners and operators in the surrounding areas, ensuring that our clients receive unmatched maintenance and care.

Our Service Offerings

Our array of expert services is tailored to meet the specific needs of your trucks

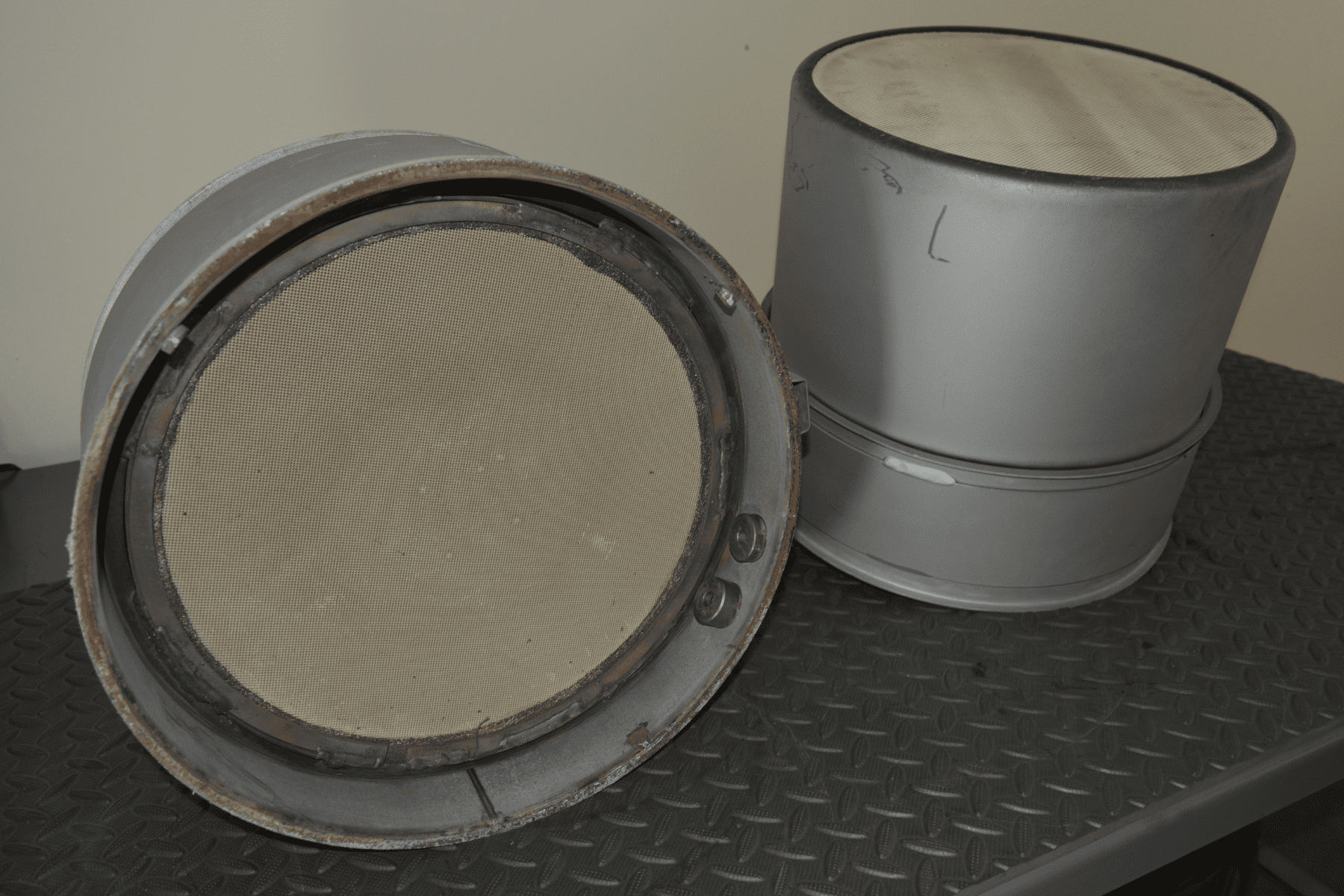

DPF Cleaning

Enhance your truck's performance with our thorough diesel particulate filter cleaning service. We ensure that your DPF operates at peak efficiency.

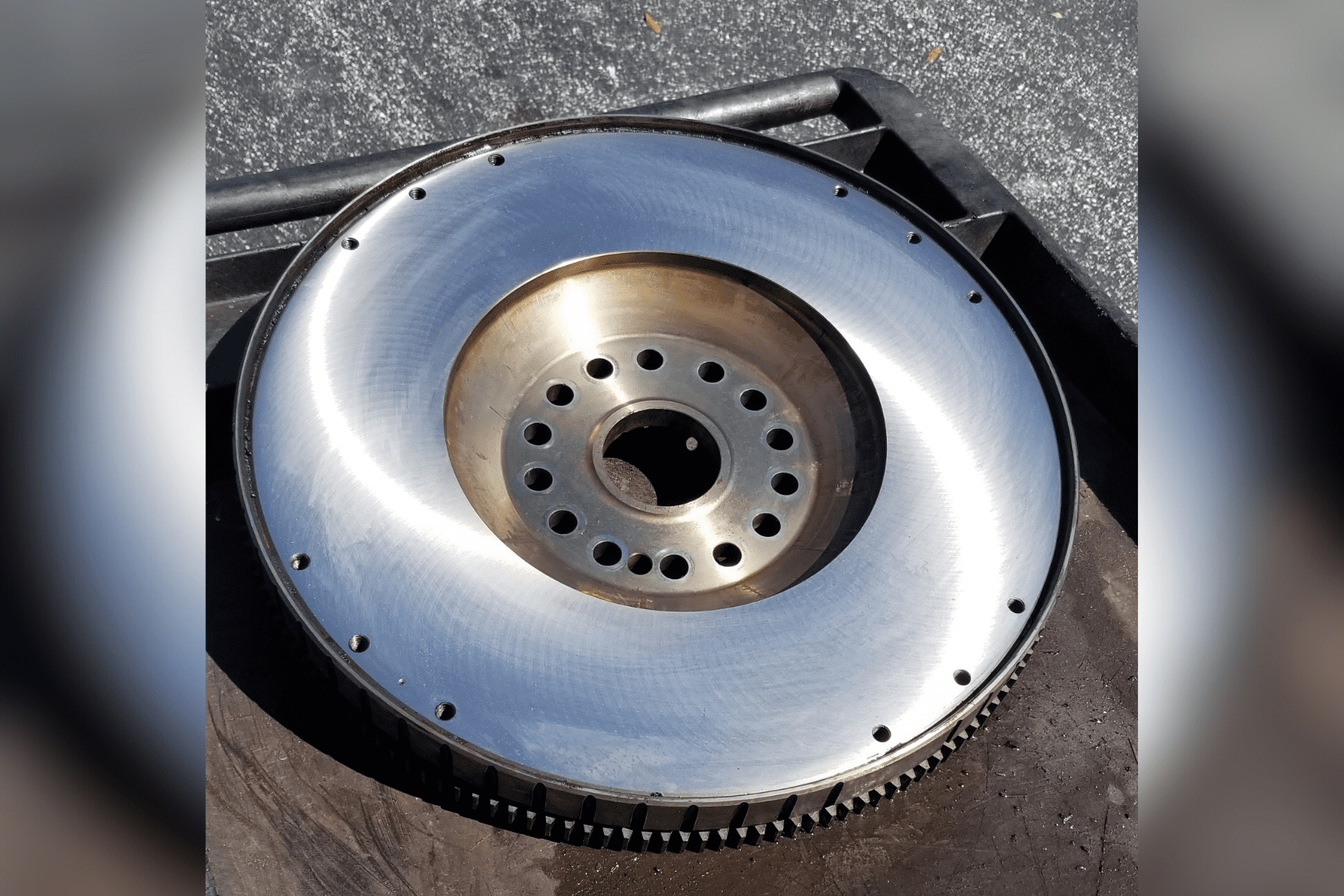

Flywheel Resurfacing

Extend the lifespan of your truck's clutch system with our professional flywheel resurfacing service.

EGR Cooler Cleaning

Our expert team cleans and maintains your exhaust gas recirculation (EGR) cooler, reducing engine temperature and improving fuel efficiency.

DEF and Parts Available

Keep your diesel exhaust fluid (DEF) system clean and functioning correctly to prevent costly repairs and ensure optimal performance.

Clamps and Gaskets

We provide high-quality clamps and gaskets to secure and seal your truck's components, preventing leaks and ensuring durability.

Catalytic Converter Cleaning

Maintain the effectiveness of your truck's emission control system with our specialized catalytic converter cleaning service.

Schedule Your Service Today

Whether you need DPF cleaning, EGR cooler cleaning, or flywheel resurfacing, reach out today. DPF Solutions has the expertise and tools to keep your trucks running at their best.

Cleaning Process

Pneumatic Cleaning (Approx. 60 Minutes)

The pneumatic cleaning process takes place using the FSX TrapBlaster, which is the primary method for removing accumulated ash and soot from the DPF. During this process, high-pressure air jets scan both ends of the filter. These jets target each of the filter's individual cells to effectively remove as much dust as possible.

Thermal Cleaning (Approx. 12 Hours)

The thermal cleaning process is performed using the FSX TrapBurner. The DPF is heated to oxidize soot trapped within the filter and loosen ash deposits. This method also helps eliminate oil residue that could interfere with the pneumatic cleaning. Thermal cleaning is not required for every filter; inspection and testing will determine when this process is necessary.